“Due to the coronavirus, the major automakers were experiencing declines in January and February, compared with the same period in the previous year,” said Jinyong Fu, RSM China partner and automotive leader. “However, many of the manufacturers have resumed their production (although not at full capacity) after the Lunar New Year when the epidemic had been controlled effectively.”

As automakers work to reopen factories and parts plants resume operations, many suppliers have no choice but to turn to costly airfreight, rather than ships, to get parts to their customers quickly. Supply chain issues may force businesses to send workers home or reduce production in the near-term.

As the coronavirus takes its toll on Italy, the world's eighth biggest economy, Lamborghini announced the closing of its factory in Sant’Agata Bolognese. Because this facility is responsible for the production of all the brand’s models, this effectively means no new Lamborghini production. In addition, Fiat Chrysler has temporarily closed four plants in Italy.

Automotive companies around the world are increasing space between employees at their workstations, according to RSM Italy’s automotive team. This will affect and require changes to the manufacturing process, and when production resumes may lead to lower daily production rates. These changes, plus enabling employees to work from home, will bring major challenges for companies to meet production demands globally.

The automotive supply chain in Europe is highly integrated, with supply chains that cross multiple countries. Germany is the global headquarters to Volkswagen, BMW and Daimler. Renault and Peugeot, which is merging with Fiat Chrysler, are based in France. As France and Germany continue to evaluate the pandemic, and provide directives and restrictions to contain the coronavirus, car manufacturers will continue to feel the impact and pressure in their supply chains.

How coronavirus may transform auto sector

There may be a surge in growth in the automotive market as manufacturers resume operations, but it will take time to get back to normal production levels. There is still the threat of U.S. tariffs on automobiles and auto part imports, expiring credits for electric vehicles in China, as well as new European Union emissions rules kicking in this year and in 2021. Tariffs—which have increased costs—as well as the increased research and development costs (such as electric vehicle and autonomous vehicle technology) to comply with new regulations and increasing consumer demands could do serious damage to the bottom lines of the weakest global players.

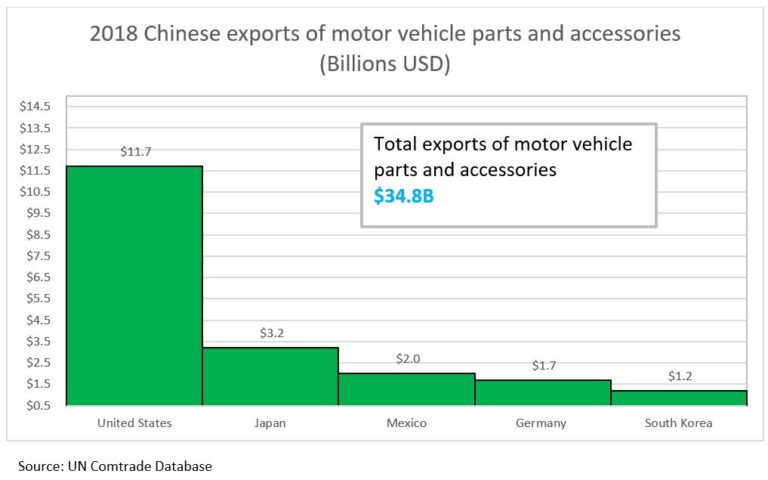

The coronavirus outbreak will surely accelerate industry consolidation and transformation, with organizations focusing on greater resiliency, innovation and investment in emerging growth markets. Significant disruption inevitably causes companies to respond with a campaign to diversify their suppliers, leading to higher costs in the short-term. Those higher costs typically ease as the memory of the disruption fades, but this time may be different; manufacturers were already shifting global supply chains away from China in response to tariffs, and this pandemic could be just the event that leads to more regionally focused supply chains. Such a reversal would mark a departure from the three-decade-plus trend of moving manufacturing to China.

Responding to change

In the short-term, our RSM automotive leaders recommend the following:

- Supply chain stabilization: The process of moving products from supply through production and eventually distribution presents complex decisions. We recommend modeling supply chain alternatives with smart algorithms and other tools to determine the best options that would provide short-term stability and a platform for long-term success. The coronavirus has highlighted a number of risks and exposures throughout the entire supply chain. Companies are looking to stabilize their supply chains in an effort to prepare for a restart and economic recovery, whenever that occurs.

- Maximize liquidity: The automotive industry is very capital intensive, requiring significant annual investments in research and development. While companies typically focus on profitability metrics, we recommend that right now companies shift their focus to enhancing liquidity opportunities. Cash conversion cycles and inefficient uses of internal cash-working capital maximization (payables, receivables and inventory) should be a secondary focus area. In general, it takes more than the CEO or chief financial officer to identify and take advantage of liquidity opportunities. Organizational behavior will need collaborative awareness and a coordinated plan for execution and the identification of key performance metrics for measuring liquidity maximization. Finally, companies need to evaluate existing lines of credit for market terms and assess alternative liquidity sources that may be available to source and fund working capital needs.

- Stay focused on your customers: We recommend companies focus on customer supply chain needs during these volatile times. Customer centricity is the quality of an organization that places the customer at its core. This standard moving forward will obviously have huge effects on supply chain design, in order to meet increasingly complex customer requirements.

Bringing stability to your supply chain, maximizing liquidity and focusing on the customer is critical in the short-term to maximize your organization’s overall financial results. However, the industry’s recovery after the pandemic will require an even deeper commitment to innovation and a drive to invest in emerging growth markets in order to maintain today’s fast-moving environment.