Flexibility to innovate

Along with improved security, cloud technologies give manufacturers enormous flexibility in how they can get the most value from their data. Companies can use whatever amount of data computing and storage they may need at a given time but also can scale up as they grow and develop. That also means businesses can manage their costs more effectively.

“As companies think about smart manufacturing, which is huge and all over the place, they maybe have avoided the journey,” says RSM principal and enterprise account leader Ron Beck. “Leveraging the cloud allows them to start at their own pace.”

Manufacturing executives need to understand that cloud platforms are foundational to the smart manufacturing revolution. The extent to which manufacturers can take advantage of advanced, Industry 4.0 technologies—such as artificial intelligence, machine learning, smart devices and digital twins—will depend on the extent to which they have embraced the cloud.

Companies need to take action now to be able to adopt these technologies if they want to stay competitive, especially given that levels of Industry 4.0 adoption increased across almost all business functions over the last year, according to the Manufacturing Leadership Council’s 2021 Factories of the Future survey. We expect competition in this area to keep heating up; the MLC found that 41% of manufacturers will continue to accelerate adoption of Industry 4.0 technologies in light of the pandemic.

"The cloud is really the enabler," says Jason Alexander, RSM principal and industrials senior analyst. “If middle market firms want to be able to innovate using today’s technology, that cloud infrastructure is like a baseline and foundational component to that.”

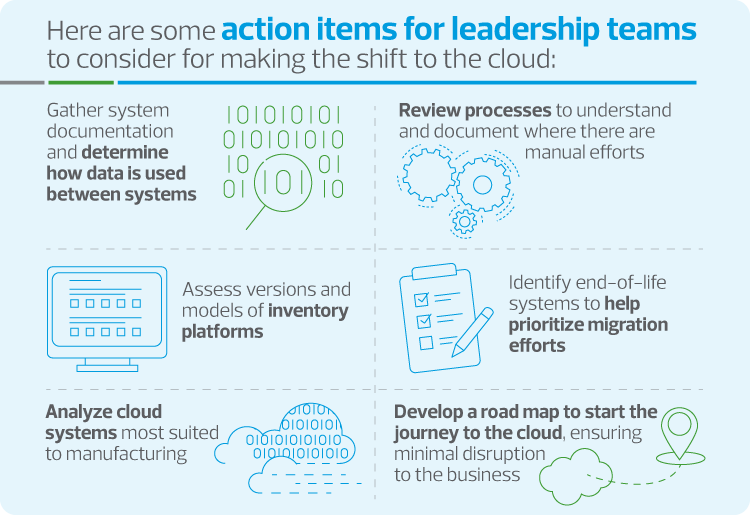

Charting a path forward

The shift to the cloud can be an unwieldy endeavor without proper planning. Executives should create a transformation road map to identify their current phase of adoption, and to decide how they want to accelerate that adoption in the future.